Heat Exchanger Cleaning

Expert Solutions for Maximum Efficiency and Equipment Longevity

Reflow's heat exchanger cleaning services restore performance, reduce energy costs, and extend the life of your critical equipment.

Why Clean Your Heat Exchanger?

Regular cleaning of heat exchangers is essential to maintain optimal heat transfer, reduce energy consumption, and prevent equipment failure. Fouling and scaling can significantly impact efficiency, leading to increased operational costs and downtime.

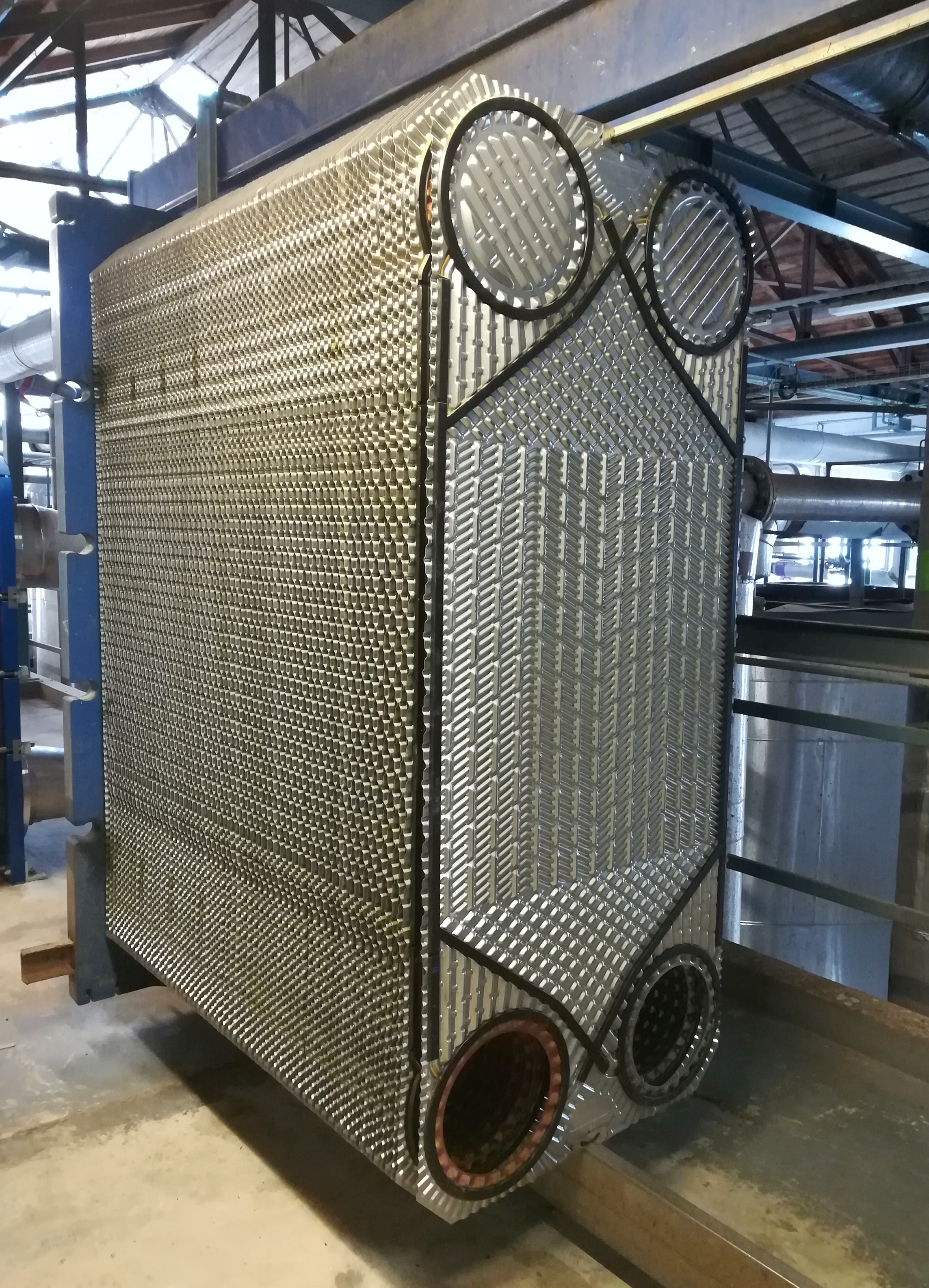

Plate Type Heat Exchanger Cleaning

Removing scale and fouling from plate surfaces to restore heat transfer efficiency.

Shell & Tube Heat Exchanger Cleaning

Cleaning tube interiors and exteriors to maximize performance and prevent corrosion.

Chiller Tube Cleaning

Removing biological growth and deposits to ensure reliable chiller operation.

Oil Cooler Cleaning

Removing oil residues and contaminants to maintain optimal cooling.

Feedwater Heater & Cooler Tube Cleaning

Preventing scale and corrosion in critical boiler and process systems.

Rotary Heat Exchanger Tube Cleaning

Specialized cleaning for rotary exchangers to maintain air quality and efficiency.

Our Cleaning Methods

- Chemical Cleaning: Safe, effective chemical solutions to dissolve scale and fouling.

- Mechanical Cleaning: High-pressure water jetting, brushing, and scraping for tough deposits.

- Eco-Friendly Cleaning: Environmentally responsible products and processes.

Contact Reflow today to schedule your heat exchanger cleaning and experience improved efficiency, reliability, and cost savings.